Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

Technological

Next-Gen AI-Driven Fiber Laser Cutting Machines: The Future of Precision Manufacturing

The manufacturing industry is rapidly evolving, and one of the most exciting advancements is the integration of AI into fiber laser cutting machines. While many small metal workshop owners consider AI-related equipment too extravagant for traditional processing, its adoption significantly reduces labor and energy costs while minimizing production defects. Trumpf's release of its first AI-driven laser cutting machine on the 25th of this month is a significant event. It clearly signals to the laser cutting machine industry, and even the broader machine tool equipment sector, that the benefits of the AI era are not limited to the digital realm. Physical manufacturing can and should indeed capitalize on the advantages that artificial intelligence offers. These next-generation machines are transforming metal fabrication by improving precision, efficiency, and automation. Companies around the world, especially SUDA fiber laser cutting machine from China markets, are adopting AI-driven systems to stay competitive.

Current CNC laser cutting machine models rely heavily on manual programming and operator expertise. However, AI-powered systems can analyze cutting patterns, adjust parameters in real time, and even predict maintenance needs before breakdowns occur. For example, some of the latest metal laser cutting machine models use machine learning to optimize cutting paths, reducing material waste and energy consumption. This is particularly useful in industries that require high precision, such as aerospace and automotive manufacturing. The SUDA SD6060 series is renowned for its high precision, making it ideally suited for the demanding precision machining of aerospace and automotive equipment.

One major benefit of AI in metal sheet laser cutter technology is its ability to enhance edge quality. In the past, achieving smooth, burr-free cuts on thick metals required extensive trial and error. Now, AI algorithms can automatically adjust laser power, speed, and focus based on material type and thickness. This leads to faster production times and fewer defects. Additionally, AI-driven systems can detect inconsistencies in material quality, ensuring that every cut meets customers' strict requirement.

Another key innovation is the use of AI for predictive maintenance. Traditional fiber laser cutting machines require scheduled downtime for inspections and part replacements. AI-enabled systems can monitor wear and tear in real time, alerting operators before critical malfunction. This minimizes the loss of unexpected stoppages and extends the lifespan of the equipment. Some manufacturers are even building in IoT connectivity, allowing remote diagnostics and software updates.

The demand for smarter, more efficient laser cutting solutions is growing, particularly in China, where manufacturers are investing heavily in automation. Companies like Trumpf and Bystronic have already introduced AI-Driven machines that offer faster processing speeds and greater flexibility. These machines are not only more productive but also easier to operate, reducing the need for highly skilled technicians. That can help reducing cost alot.

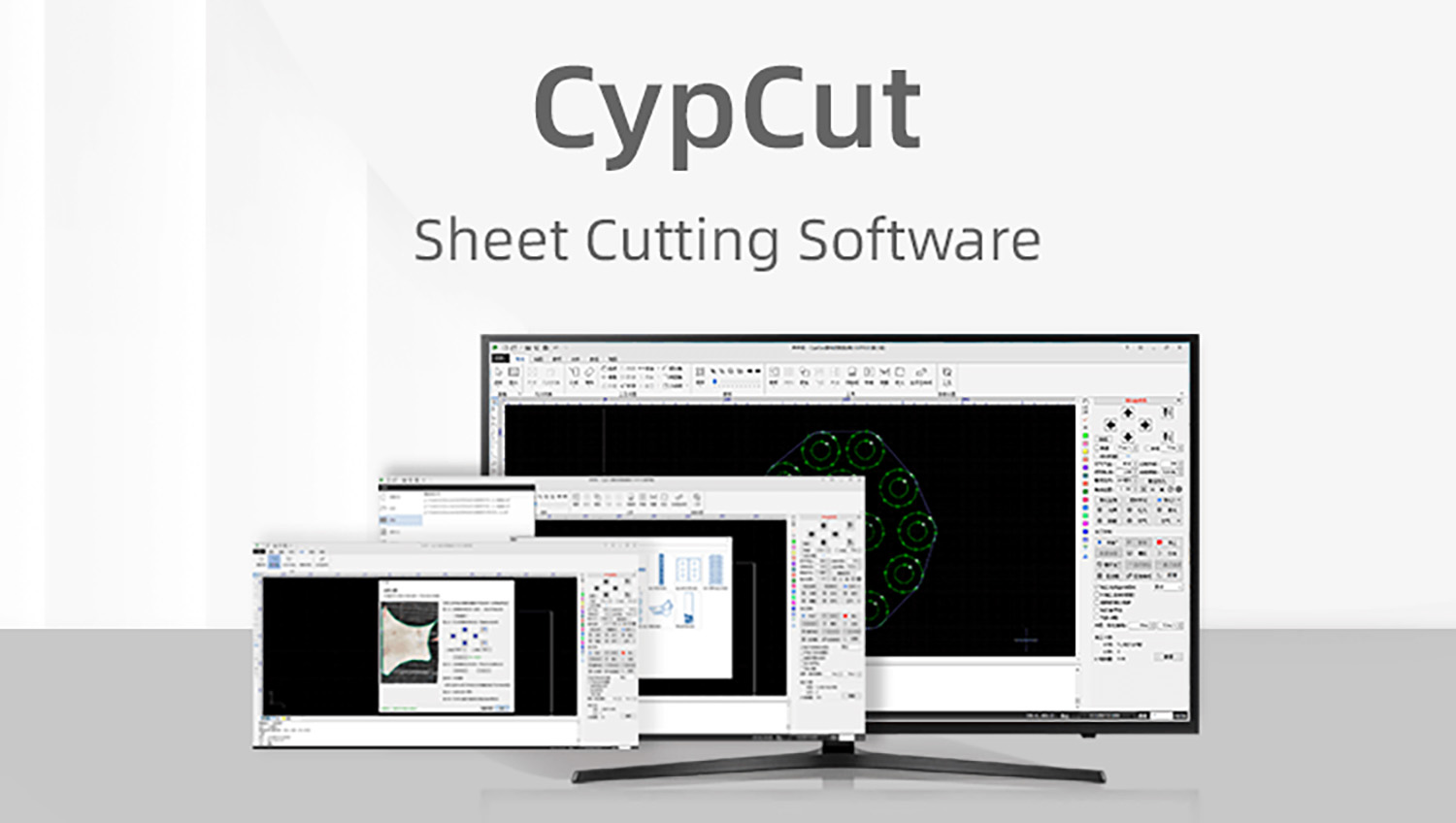

It's actually quite simple to equip a laser cutting machine with an AI intelligent control system. This can be done by just upgrading the control system (for example, Weihong or CypCut) and getting the manufacturer's latest upgrade kit to enable the AI functions. Or, by installing third-party detection software on the control computer, you can easily give your laser cutter intelligent detection and adjustment capabilities.

Leave a Comment