Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

Technological

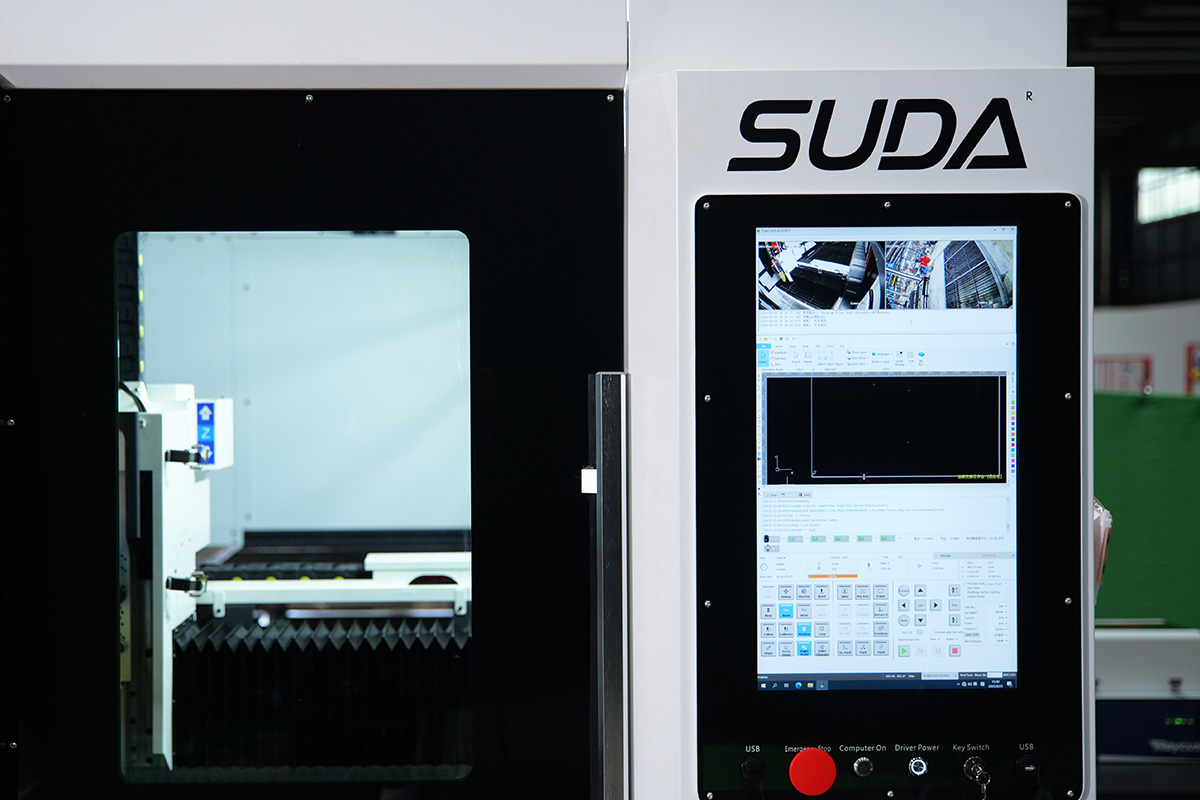

More Than a Laser Brand Why Our F Series Is Engineered for Real World Reliability

We frequently encounter clients who, during initial inquiries, focus solely on "what's the price?" and "what's the laser power?" while paying little attention to the factors that truly matter. Questions about the laser brand, the machien bed material and heat-treatment process of the machine bed, or the brands of servo motors and reducer are often overlooked. There is little point in rushing to ask about price and power without first clarifying these critical configurations. None whatsoever! When you are making a substantial investment in a machine, it is unwise to compromise on quality for the sake of saving what might only be a fraction of the total cost.

When you invest in a fiber laser cutter, the laser power and brand are crucial starting points. However, true productivity and uptime are determined by the complete system built around that laser. Since we began specializing in laser technology in 2006, grounded in over three decades of CNC machinery expertise dating back to 1992, we have focused on one goal: perfecting the integration of every component. A great laser deserves a world-class machine to hold it.

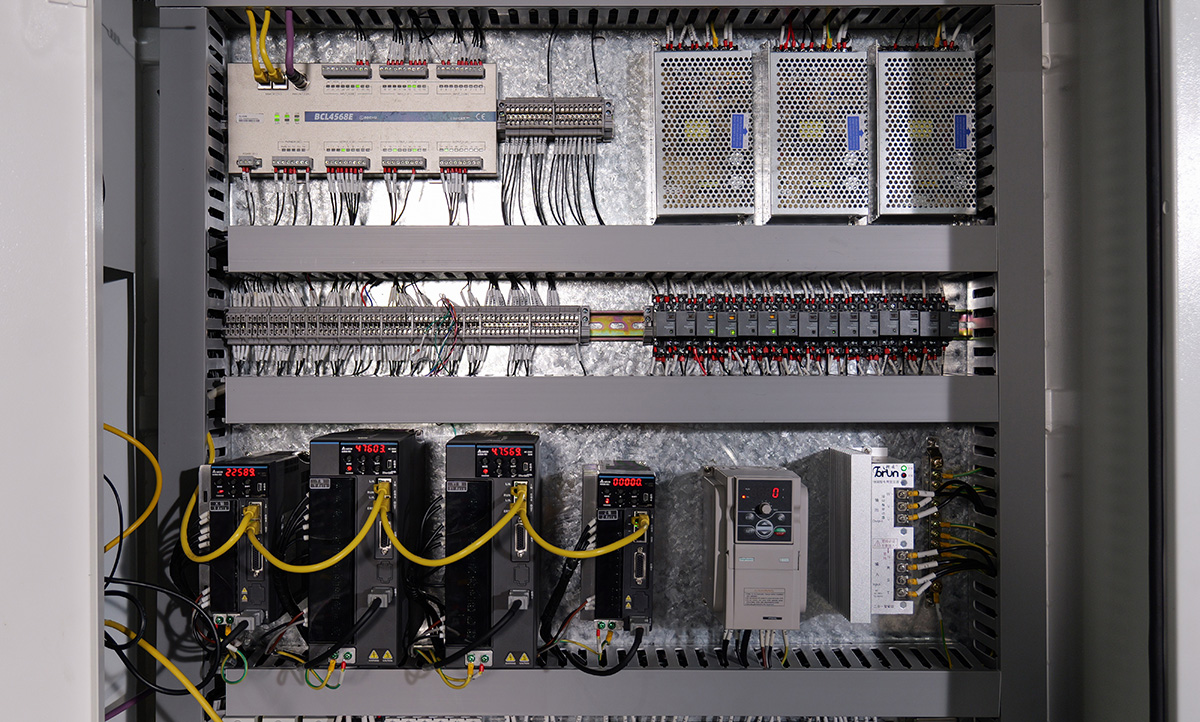

Take our foundational F3000 series as a prime example. This robust single-platform machine, equipped with reliable Raycus or Reci lasers up to 6kw, is built for precision. But its renowned consistency comes from the synergy of its core components. The laser's potential is unlocked by a high-stability motion system utilizing THK or SMC linear guides, Delta servos, and Shimpo reducer. This ensures rapid, vibration-free acceleration and deceleration, which is critical for cutting sharp corners and complex geometries without compromise. Simultaneously, the vital task of thermal management is entrusted to genuine Hanli or S&A industrial chillers. Their precise temperature control, often within ±0.5°C, is not a luxury; it is essential for maintaining the laser's beam quality and protecting the pump source from thermal damage, thereby ensuring consistent cutting performance and long-term reliability.

For heavier industrial demands, our F-Pro Fiber Laser Cutting Machine supports powers up to 12kw with advanced Raycus or IPG laser sources. Our flagship FV series, designed for the highest power levels and equipped as standard with a large shuttle table, is engineered for maximum throughput in continuous operation. Across all models, our philosophy remains the same: superior system integration. We ensure the laser source, the robust electrical framework, the rigid steel structure, and the precision cooling system operate in perfect harmony. This transforms raw power into predictable, profitable performance that stands the test of time.

This commitment to quality is backed by a global promise. Serving clients in over 130 countries, we support every installation with expert on-site service and the confidence of a comprehensive lifetime warranty. You are not just purchasing a collection of parts; you are investing in a fully engineered production solution built for real-world reliability.

After-sales service is arguably the true hallmark of a premium fiber laser machine. Over the years, we have encountered numerous clients who initially purchased cheap machines from obscure manufacturers now seeking our help, asking if we can assist with repairs or provide spare parts for those brands. The reason is simple: they were lured by unrealistically low prices, and now those small workshops have vanished without a trace, leaving their warranty promises utterly void. We must politely decline these requests because those poorly built machines often use unverified components and, most critically, feature unstable machine frames --the very foundation of precision and longevity. This is a fundamental flaw that no amount of subsequent repair can ever rectify. On the other end of the spectrum, while machines from major European and American brands are known for their reliability, a fiber laser cutter remains a precision instrument that will inevitably require maintenance. Their repair costs, however, are prohibitively expensive. SUDA Laser strikes the ideal balance between exceptional quality and manageable maintenance costs. As a manufacturer with over 30 years of history, our after-sales service is built on a foundation of trust and long-term commitment.

Leave a Comment