Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

Technological

How SUDA Fiber Laser Cutters Build EV Integrated Battery Chassis

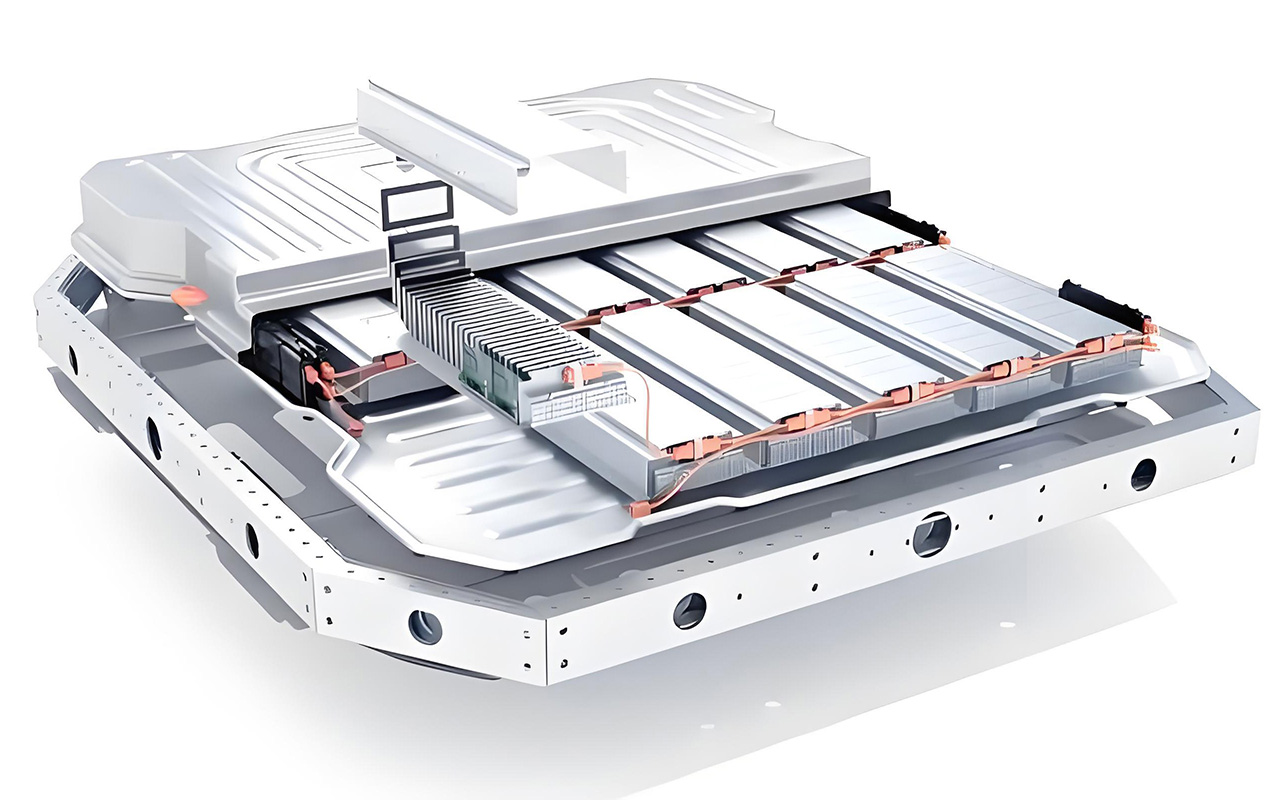

The electric vehicle industry is growing fast. A key part of modern EVs is the integrated battery chassis. This single strong unit combines the car's frame with its battery pack. It makes EVs safer, lighter, and gives them more range. At SUDA Laser, we understand the evolving needs of the EV industry. Our advanced gantry type 4 axis fiber laser cutting machines are perfect for making these complex EV parts.

For over 30 years, SUDA has been a leader in CNC technology. We build reliable machines that help factories produce high-quality products. Our focus on precision and efficiency makes us an ideal partner for the EV sector. We make several key machines that are vital for creating integrated battery chassis. These include fiber laser cutting machines, CNC routers, and press brake.

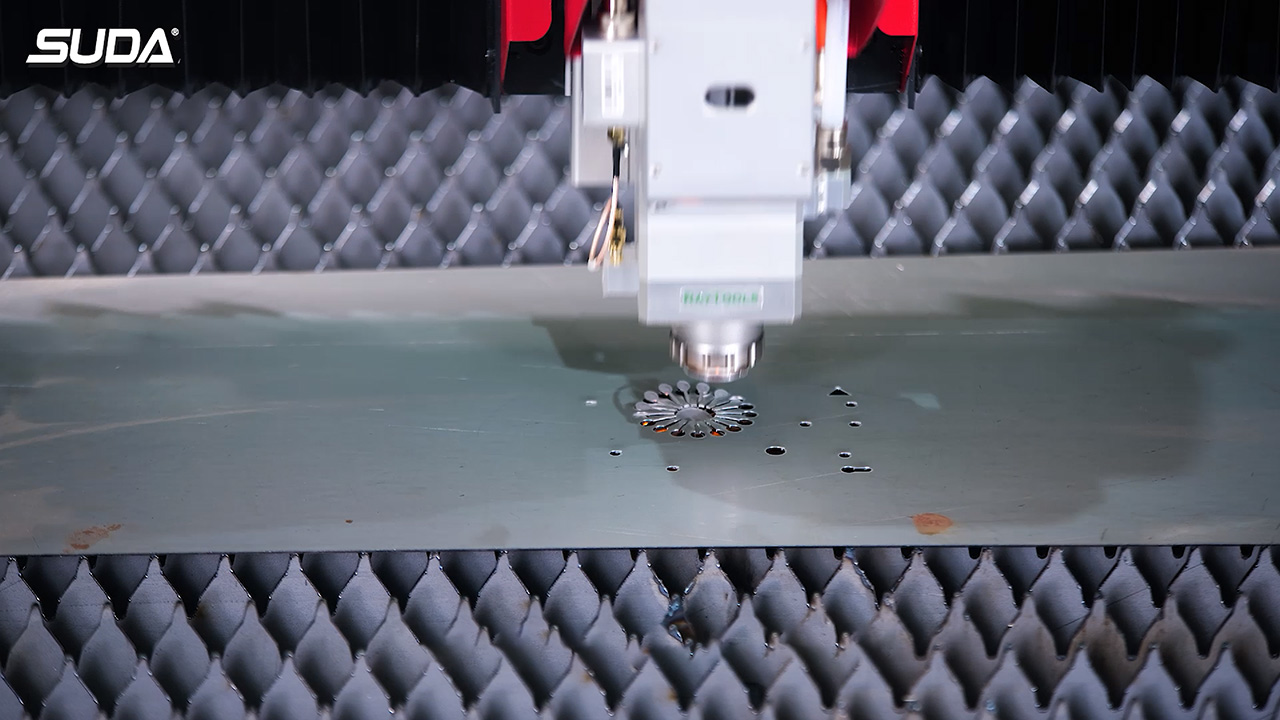

Building an integrated battery chassis starts with cutting metal plates. This kind of chassis often uses strong yet light materials like aluminum alloy. SUDA fiber laser cutting machines are specially built for this heavy-duty job. Unlike small factories, we have our own large-scale heat treatment furnaces. Every machine frame goes through a high-temperature tempering process. This removes internal stress from the metal, ensuring the chassis stays perfectly stable and never deforms, even after many years of high-speed operation. They cut metal sheets with extreme accuracy and speed. Our lasers create clean edges, which is important for strong welds later on. They can handle different metal thicknesses easily, ensuring every piece fits perfectly. This precision helps reduce waste and speeds up production.

After cutting, flat metal parts need to be bent into specific shapes. The chassis has many complex angles and curves. Our bending machines are perfect for this task. We recommend models like the SUDA 160T/4000 press brake, which provides 160 tons of pressure and a 4-meter working length. This model is ideal for handling the long, high-strength metal sheets used in EV battery chassis, ensuring every angle is precise and consistent.

While fiber lasers and bending machines handle metal, the integrated chassis might also need parts made from composite materials or plastics. For these needs, SUDA offers CNC routers. These machines are highly versatile. They can cut, drill, and shape various materials with excellent accuracy. For example, our high-end SUDA S6 gantry type CNC Router is perfect for this. With its powerful 9kW water-cooling spindle and a vacuum dust collector system, it can create precise housings or covers for battery components, and even produce prototype parts quickly with a clean working environment. Our 30 years of experience in CNC technology ensures these routers are robust and reliable for continuous operation.

Why Choose SUDA for Your EV Chassis Production?

Accuracy: Our machines ensure every cut and bend is perfect. This leads to higher quality chassis.

Efficiency: Faster cutting and bending speeds mean you can produce more chassis in less time.

Reliability: With 30 years in the CNC business, SUDA machines are built to last and perform consistently.

Complete Solution: From cutting to bending and shaping, we offer a range of machines that work together.

The future of EVs is integrated. SUDA is ready to help you build that future, one precise cut and bend at a time. Partner with SUDA for advanced manufacturing solutions for your EV integrated battery chassis. Learn more about our fiber laser cutting machines, CNC routers, and press brake today.

Leave a Comment